E-Mobility

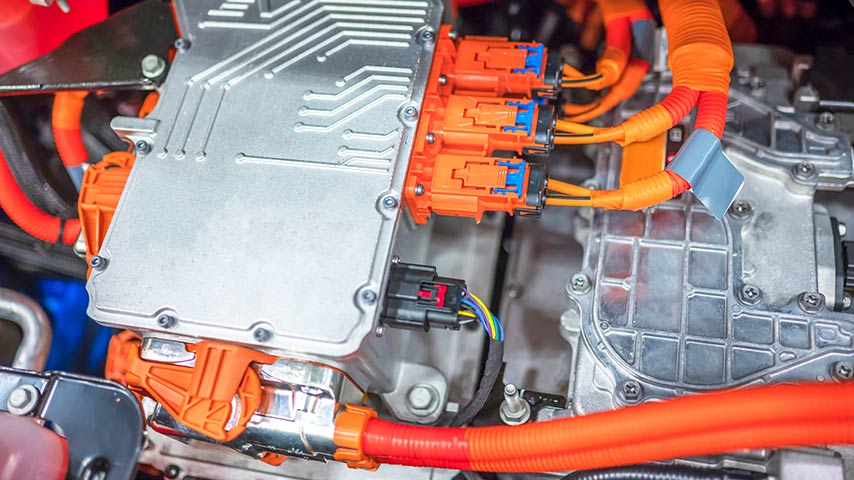

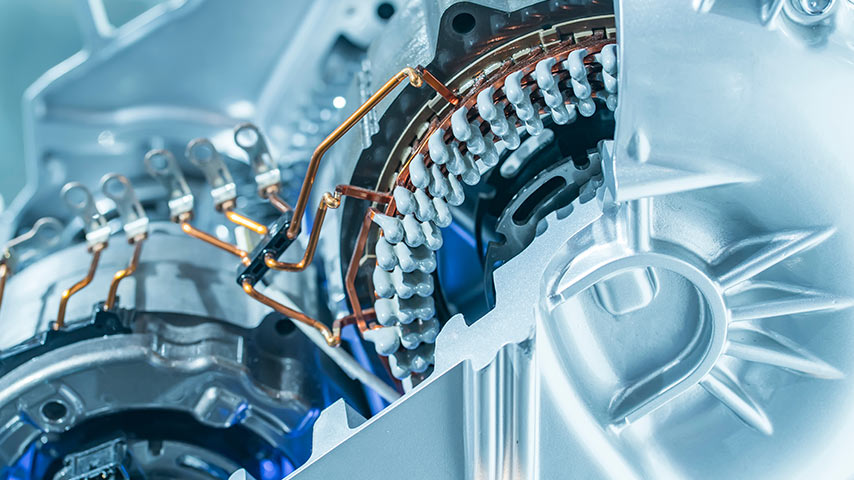

Partnership connectsThe field of e-mobility is growing rapidly. In order to be able to map the growing market and the resulting opportunities, Beutlhauser GmbH & Co. KG has expanded its long-standing partnership with Otto Bihler Maschinenfabrik.

The cooperation between Beutlhauser and Bihler has already existed for several years and has resulted in many successful projects. A complex market, which requires a lot of know-how, flexibility and speed, needs good and reliable partnerships.

Through years of experience, we can jointly demonstrate many application areas of our customers in the field of E-Mobility.

.

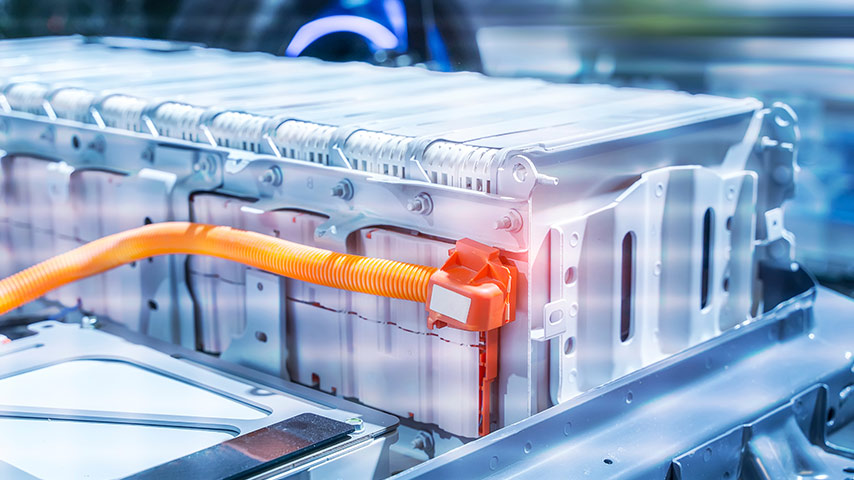

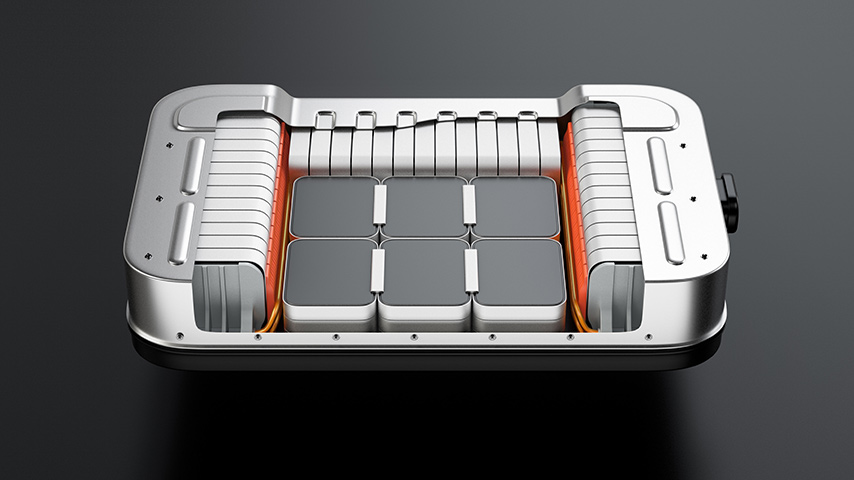

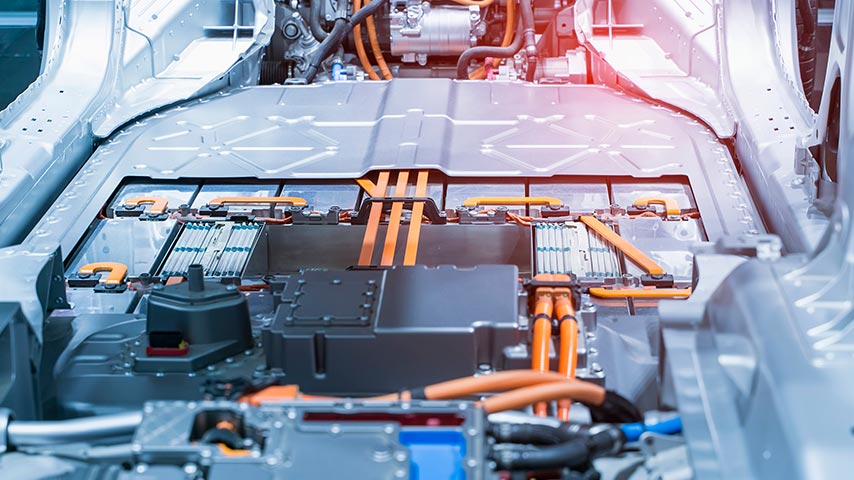

Busbars are electrical power distribution devices used not only in automotive applications, but also in many high current flow applications.

Some examples: Switchgear construction, mechanical engineering, rail construction, telecommunications or renewable energy construction.

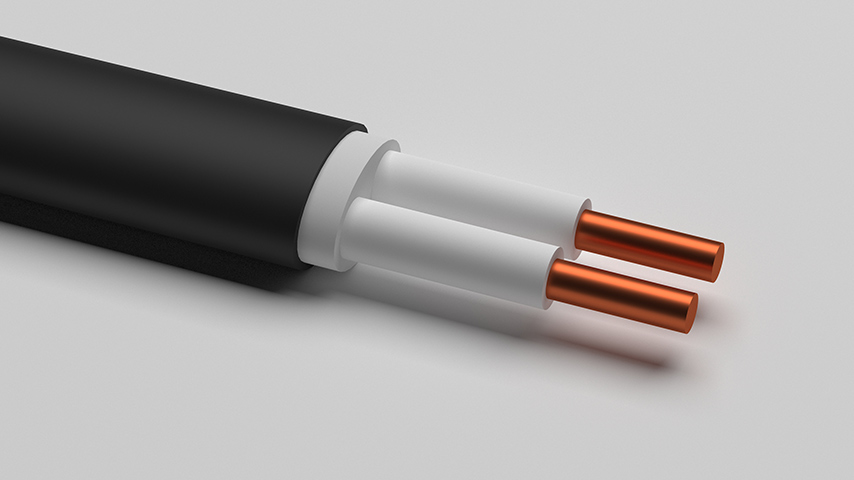

Busbars come in different shapes and geometries. They are made from flat strip, sheets, flat wire, round wire or rods.

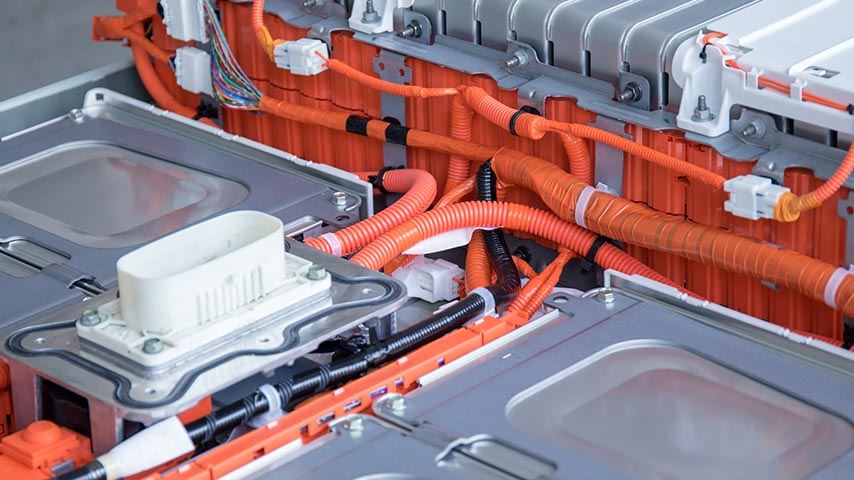

The semi-finished products are processed differently depending on the application. A wide variety of technologies are used for this purpose.

For prototype construction, we can draw on a large machine park to realize small quantities. Here, for example, the blanks are cut from plates. For this purpose, we use a wide variety of technologies in our company:

– Water jet cutting (this process is used to avoid heat input into the raw material)

– Laser cutting (this process is very fast and cost-effective)

– Eroding technology (this method is used when very dimensionally accurate components are required)

In the series production process, high-precision stamping and forming tools are required to produce increasingly complex busbars. Further processing of the molded parts produced requires a well thought-out manufacturing strategy in the design of the process chain.

In today’s world, busbars are not just bus bars that conduct energy. Sophisticated coatings are used to insulate components from each other or to ensure that currents can flow better in order to minimize transmission losses.

In this area, we work together with the customer to develop the most effective surfaces and implement them in series production.