Stamping technology

Stamped, stamped-bent, drawn and inserted parts I Construction componentsPerformance through state-of-the-art technology

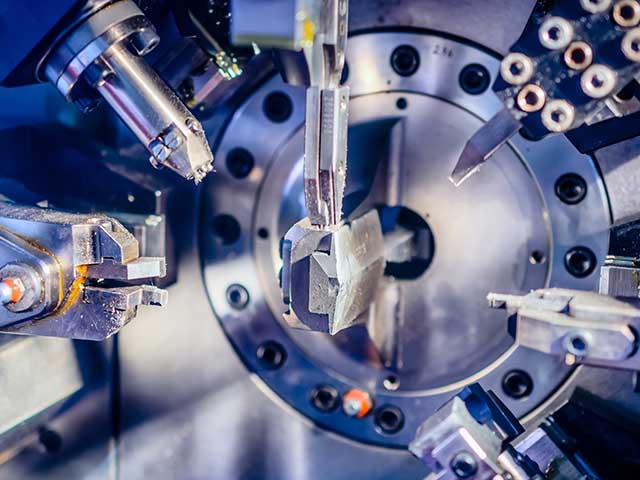

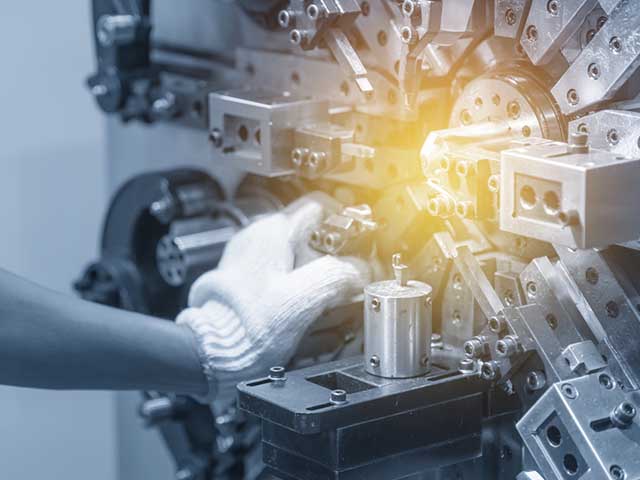

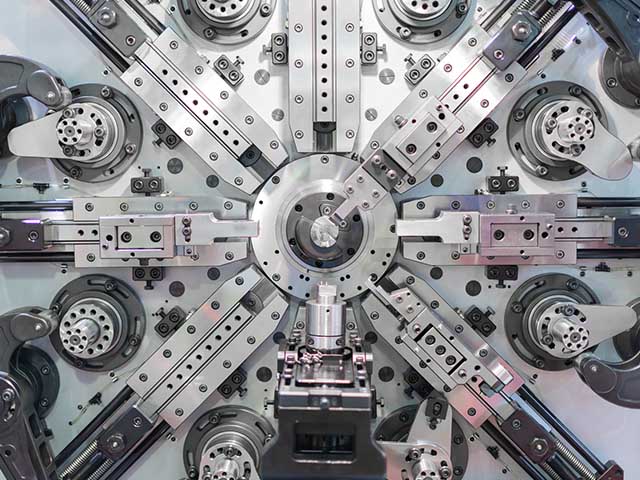

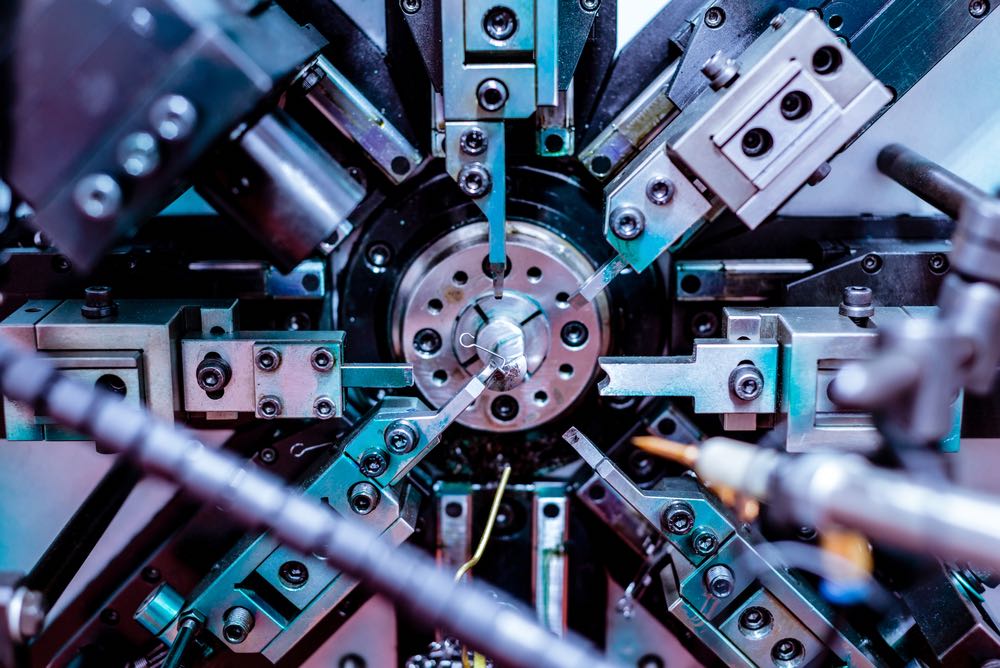

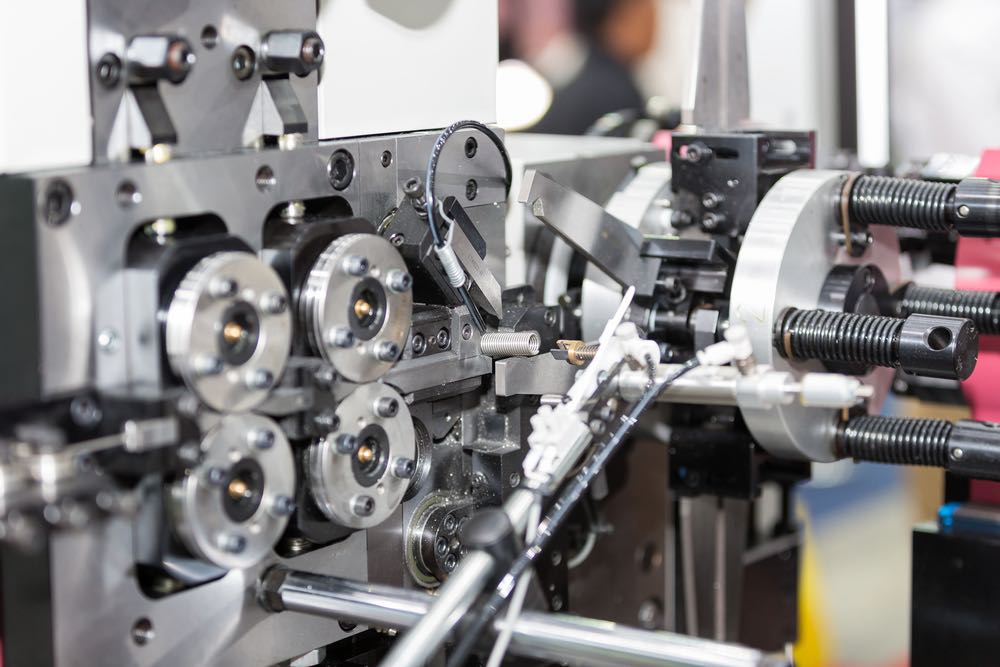

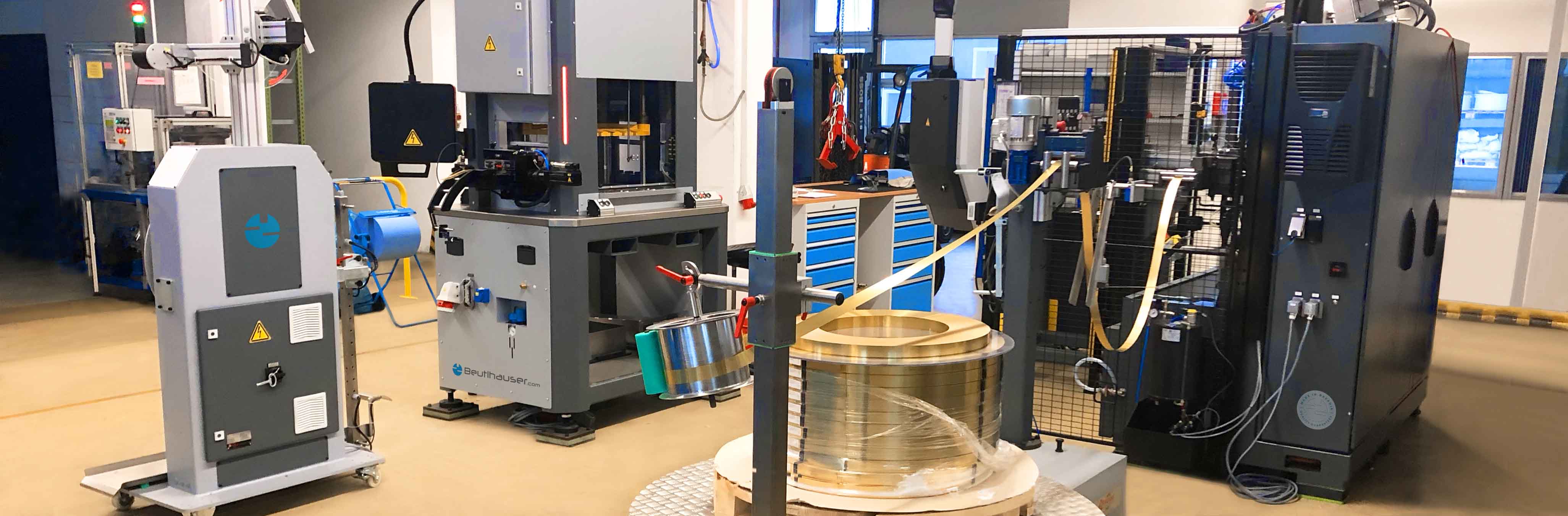

We manufacture precision drawn and stamped-bent parts on high-quality “Bruderer” stamping machines and modern „Bihler” automatic stamping presses. State-of-the-art process monitoring and lifting speeds of up to 1000 strokes/min. enable us to manufacture economically, safely, precisely and to high quality.

From the first prototypes to series production, we can offer you everything from a single source.

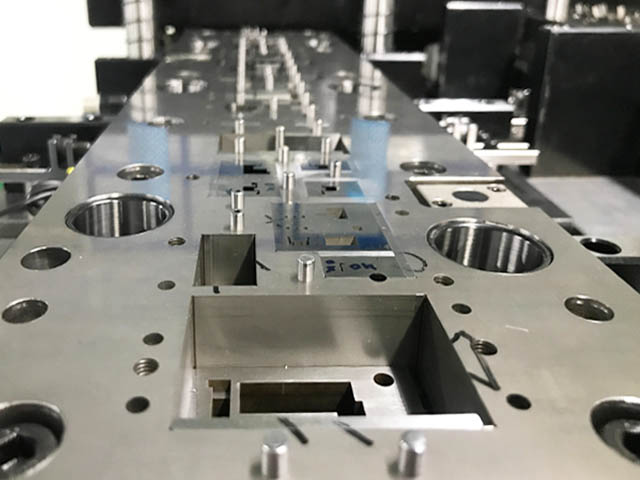

We design and manufacture sophisticated progressive tools made of tool steels, powder metallurgical steels and hard metals. Our own tool construction is equipped with the most modern machines. This enables us to implement customer requirements quickly and precisely.

Stamping technology

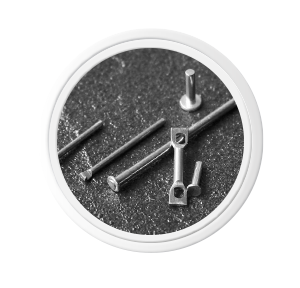

We manufacture stamped, stamped-bent, drawn and inserted parts as well as construction components from all common materials and according to customer specifications.

Surface technology

Through strong partner companies we offer our customers pre- and post-treatment services:

Gold plating I Silver plating I Nickel plating I Chrome plating I Burnishing I Phosphating I Tin plating I Galvanising I Pickling I and much more

Shaping

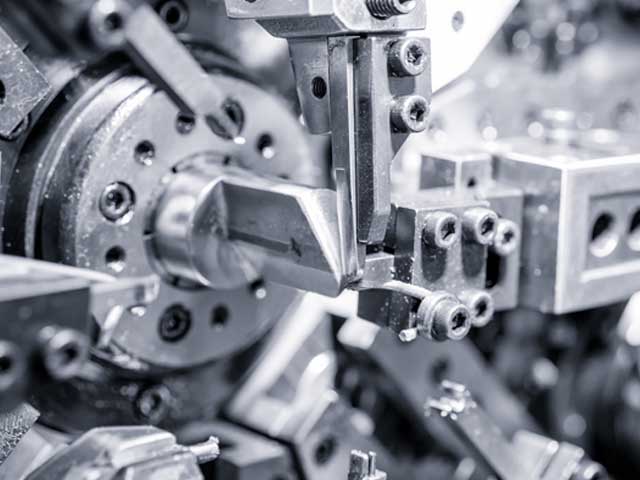

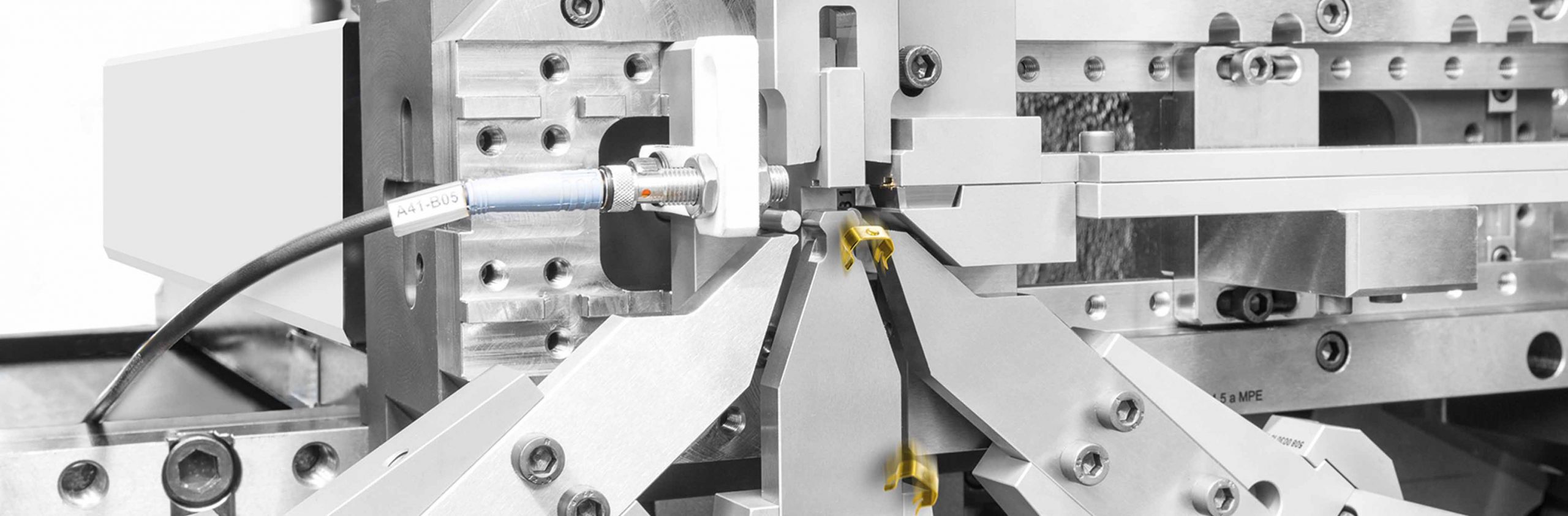

Punching I Bending I Embossing I UpsettingPrecision made of wire

A large machine park combined with in-house toolmaking enables us to manufacture products of the very highest quality. We produce individual samples up to large series quickly and directly.

We manufacture in all alloys and in all dimensions and shapes.

Wire processing

- Punching

- Bending

- Hole punching

- Embossing

- Upsetting

- Cold forming of round and shaped wire in the range of 0.1 mm to 6 mm

- Bent parts from springs up to three-dimensional shapes

We manufacture contact pins in bond quality.