Separation technology

Cutting saws I Cut-off grinding I Shape cut-offsWe meet every challenge

By using our special machines with particularly high-quality automatic cut-off machines, we can achieve very precise results that meet the highest requirements.

Production-accompanying inspections and outgoing goods inspections are the guarantee for highest quality.

Cutting & grinding technology

Whether cutting saws, cut-off grinding or shape cutting:

We guarantee

- burr-free edges

- smallest tolerances

- highest surface requirements

We manifacture

- precision parts made of pipe and solid materials

- dimensions and alloys on request

Specially developed tools ensure top quality and maximum productivity.

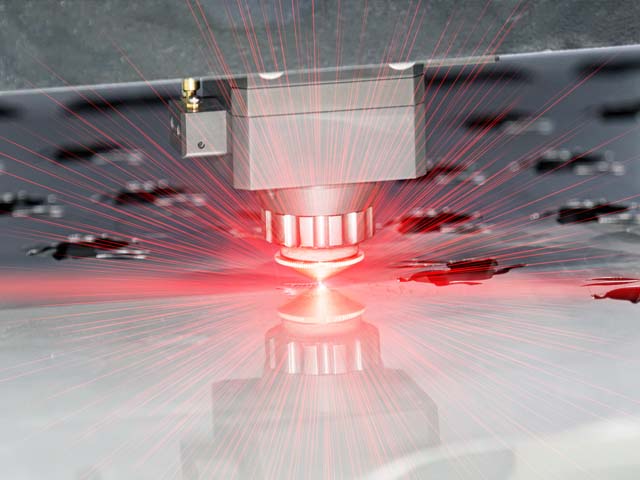

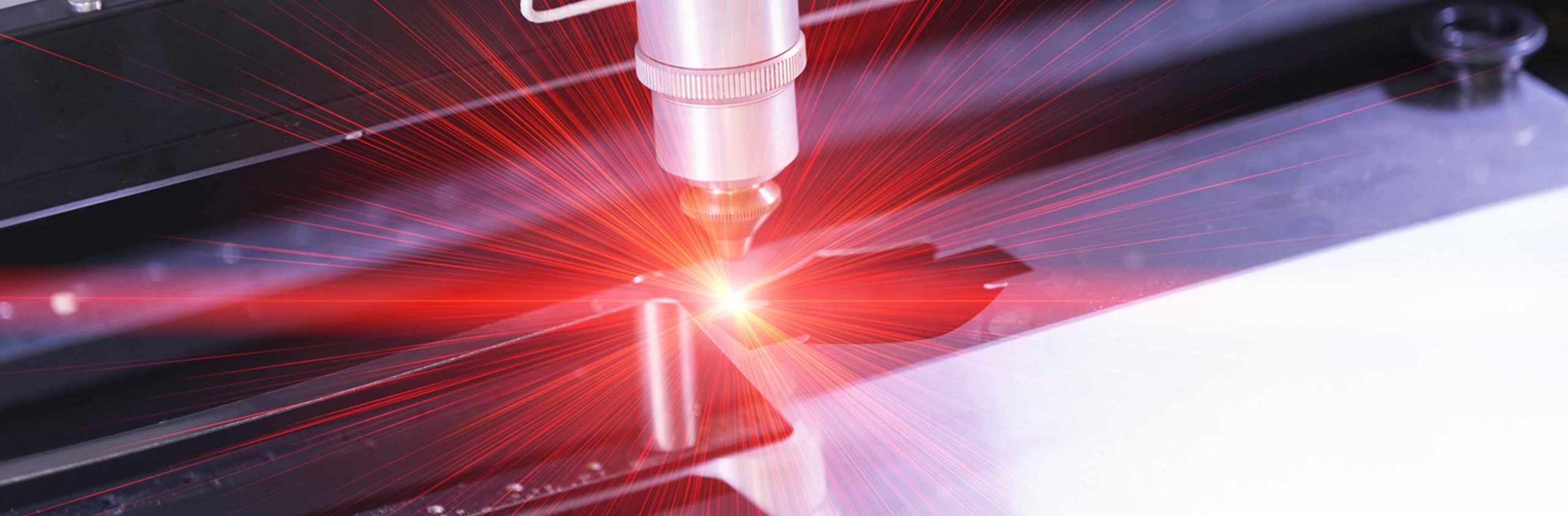

Laser machining

Labelling I Cutting I Removal

There are hardly any requirements that cannot be met by laser.

Here are some examples:

Company logo I System drawings I Special characters I Scales I Serial and drawing numbersI Variable texts I Barcodes in a wide variety of designs I Circle mantle labelling I Cost-effective marking of prototypes, small and large series

Almost all materials can be labelled, e.g.

Aluminium I Stainless steel I Tool steels I Brass I Gold I Silver I Plastics I Anodised and coated materials

Laser products

- Laser marking

Whether serial number, consecutive number, barcode, batch number, part number, logo or other types of component marking: with our laser marking we can mark your components according to your wishes. - Laser cutting

Using state-of-the-art lasers, we can join components in our stamping and forming applications during the manufacturing process using a laser welding process. - Ablation lasers

This technology is used when very precise machining is required (e.g. micro drilling, surface finishing or edge processing).

Water jet machining

Labelling I Cutting I RemovingMicro water jet cutting

Diverse components require diverse machining operations. We are looking for the most effective manufacturing option for your products.

A new pillar of our company is processing with water. For many of our special alloys, we use micro water jet cutting to prevent heat input into the products.

This technology enables a fast and clean processing of our semi-finished materials.

Do you need prototype components? We would be happy to advise you and look forward to a partnership in the field of water jet processing.

Water jet components

- Water jet cutting

With very precise machines we produce cutting contours according to your specifications. With this technology we can still produce very precise components without energy input, e.g. during laser or EDM processing of special alloys. - Preparation

We create the cutting contours and can then rework the manufactured components in a downstream process. Whether surface finish or part coating: you get a finished product from us.

Do you need an assembly? Take a look at our module production here. We will take care of your problem.

- Improvements

Continuous investment and development of our processes are a guarantee for high-quality products from our company. When working with water as a medium, many factors must be taken into account in order to be able to map efficient manufacturing processes. We meet this challenge in order to achieve the best possible results.